We are hiring! Run with Riesterer and Schnell: Apply Today

We are hiring! Run with Riesterer and Schnell: Apply Today

Search

Choose a Location

RelativeFlow blockage sensing

RelativeFlow blockage sensingWith the RelativeFlow blockage system, operators can see the flow rate of both seed and fertilizer from inside the tractor cab. Sensors on delivery hoses monitor the relative rate of product flow. An easy-to-read display clearly visualizes relative product flow across the drill, from opener to opener. This exclusive technology gives a better view of what is happening across the tool in order to spot problems before blockage occurs.

RelativeFlow Blockage is available on the following models:

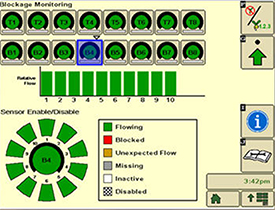

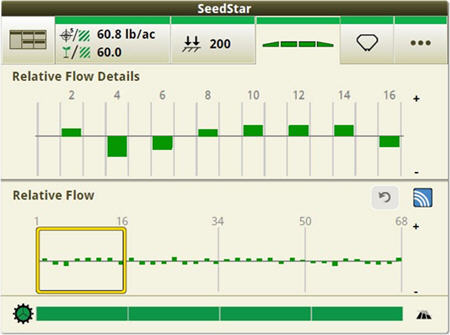

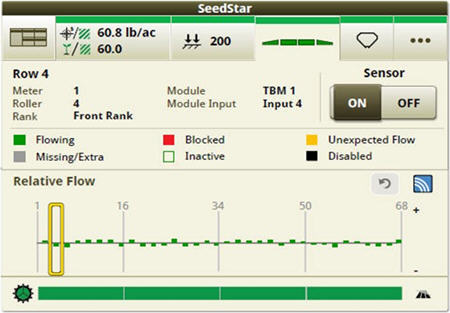

Below are the GreenStar™ 3 2630 Display screens for the blockage monitoring system. For complete details and information, see the owner’s manual.

Blockage monitoring screen

Blockage monitoring screenThe RelativeFlow system chart shows the amount of flow through each sensor on the selected tower. Sensitivity for the blockage system can be adjusted if desired, as shown below.

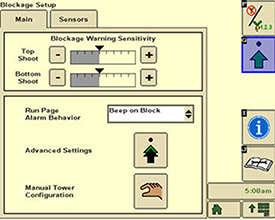

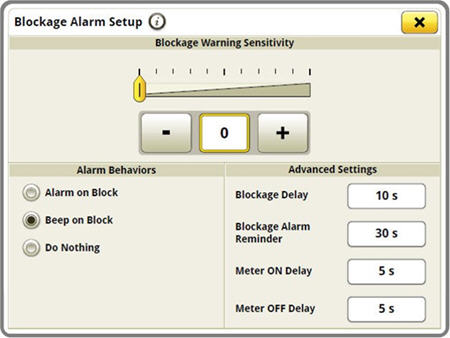

Blockage set-up screen

Blockage set-up screenBlockage warning sensitivity allows the producer to set and change the sensitivity of the sensors to meet their preferences. Increasing the sensitivity means the system is more likely to show a false blockage, while less sensitivity means the system is more likely to miss a blockage.

Multiple run-page alarm behavior options are available for selection.

Blockage set-up screen

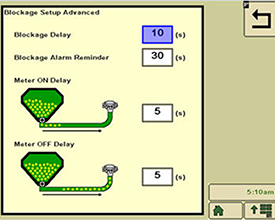

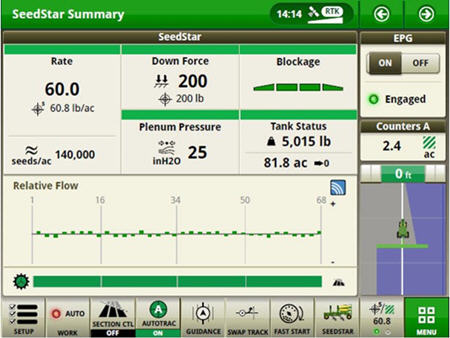

Blockage set-up screenBelow are the Gen 4 display screens for the blockage monitoring system on the N500C.

For complete details and information reference, the owner’s manual.

RelativeFlow Blockage configured run page

RelativeFlow Blockage configured run pageThe SeedStar™ system run page displays the five major run settings. Clicking on any of the tiles will take an operator to that specific page (shown below).

Operators can zoom into flow details by meter section when selecting Blockage tiles

Operators can zoom into flow details by meter section when selecting Blockage tiles Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently

Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screen

Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screenBlockage alarm delays can be set up by clicking on the advanced settings button from the blockage set-up screen.

For more detailed information, see the owner’s manual.

Weights at rear of mainframe

Weights at rear of mainframe![Wing weight bracket (shown on 18.30-m [60-ft] 1890)](http://salesmanual.deere.com/sales/salesmanual/images/NA/seeding/features_attachment/1890drill/wing_weightbracket1890.jpg) Wing weight bracket (shown on 18.30-m [60-ft] 1890)

Wing weight bracket (shown on 18.30-m [60-ft] 1890)Additional weights may be required when seeding in dry, hard soils or in extremely high rates of residue. These weights may be removed when seeding in mellow or loose soils. A rear weight bracket and a weight bracket on the front corner of each wing are in base equipment on the 9.15-m, 11-m, 12.20-m, and 12.95-m (30-ft, 36-ft, 40-ft, and 42-ft) 1890s.

The brackets allow the addition of R127764 tractor suitcase weights to provide increased down pressure. A total of 14 tractor suitcase weights can be added at the rear of the mainframe. Six tractor suitcase weights can be added on each outer wing.

NOTE: Due to the heavier mainframe on the 15.25-m and 18.30-m (50-ft and 60-ft) 1890s, mainframe weights and weight brackets are not in base equipment or required. There is an option to order kit AA76487 from service parts for the wing weight brackets.

NOTE: Order code 6505 (open-center valve kit) is not available for the 15.25-m and 18.30-m (50-ft and 60-ft) models.

IMPORTANT: Wing weights and row markers are not compatible and should not be used together.

1890 Seeding on 380-mm (15-in.) rows with rear rank

1890 Seeding on 380-mm (15-in.) rows with rear rank 1890 18.30-m (60-ft) five-section on (7.5-in.) spacing

1890 18.30-m (60-ft) five-section on (7.5-in.) spacingThe 1890 features a three-section or five-section (15.25-m [50-ft] and 18.30-m [60-ft] models) drawn flexible frame with a convenient overcenter fold for transport or storage.

NOTE: Recommended tractor is 279.6 kW (375 hp) for the 15.25-m (50-ft) model and 335.5 kW (450 hp) for the 18.30-m (60-ft) model.

Productivity of the 15.25-m (50-ft) and 18.30-m (60-ft) widths compared to the 12.95-m (42.5-ft) model:

Features on all six models:

The two-rank frame design provides excellent residue flow and field performance.

Growers have historically had to make some difficult planting and seeding decisions due to weather. Operators have been forced to plant in wet conditions that are far from optimal in order to plant within the optimum planting window. Those operators have experienced poor performance from wet soils working in between the depth gauge wheel and the opener disk and not having a way out. This creates the possibility of the depth gauge wheel or opener disk to seize up and drag through the soil.

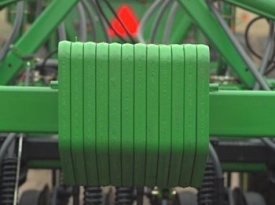

The spoke gauge wheel is a solution for operators who plant in these conditions to allow the mud and debris that get caught behind the depth gauge wheel to easily flow through the wheel and continue providing superior depth performance.

The spoke gauge wheel is designed for optimum performance. Its features include serviceable, stamped inner and outer rims. The wheel also has cast spokes and bearing hubs for increased strength. This allows smaller spokes, creating larger open surface area for mud and debris to flow more easily than competitor’s wheels. Another improvement over the closed gauge wheel is a snap-ring bearing retention. Simply remove the snap ring, replace the bearing, and place the snap ring back.

Gauge wheel

Gauge wheel Gauge wheel

Gauge wheelHeavy trash fields from no-till environments have also tested very well with the new spoke gauge wheel. Some growers provided feedback of crop residue getting inside and jamming up the gauge wheel and opener. This spoke gauge wheel has shown exceptional performance within these areas as well. These wheels are compatible with both 90 Series openers on seeding tools and planter row-units.

Below is a chart that demonstrates a competitive advantage over MudSmith™ wheels for mud and residue flow:

| MudSmith | John Deere | Percent improvement | |

| Open area | 329 cm2 (51 cu in.) | 471 cm2 (73 cu in.) | 43 percent |

| Rim height | 1.9 cm (3/4 in.) | 1.4 cm (9/16 in.) | 25 percent |

| Spoke width | 3.5 cm (1-3/8 in.) | 1.9 cm (3/4 in.) | 45 percent |

The wheel is serviceable along with other parts.

Not compatible in dual gauge wheel applications.

MudSmith is a trademark of MudSmith, LLC.

For producers using a model year 2018 and newer 15.2-m (50-ft) or an 18.3-m (60-ft) 1890 or N560F Air Drill paired with a 1910 Air Cart that may want to upgrade to a C850 Air Cart, here is the complete parts list needed to move from the 1910 to the C850.

NOTE: In both scenarios when attaching a C850 to a tool, Configurator requires option code 3205, which is a Category 5 hitch at the front of the tool.

| 15.2-m (50-ft)/18.3-m (60-ft) 1890 or N560F – Rear hitch | ||

| Quantity | Part number | Description |

| 1 | 11M7054 | Cotter pin |

| 12 | 14M7589 | Self-locking hex flange nut |

| 12 | 19M9124 | Hex head screw |

| 1 | 24M7240 | Metallic, round-hole washer |

| 8 | 34M7055 | Spring pin |

| 1 | A102680 | Plate spacer for Category 4 hitch |

| 4 | A41517 | Pin fastener |

| 1 | AA53874 | Drawbar assembly pin |

| 1 | AA88311 | Left-hand rear hitch support |

| 1 | AA88312 | Right-hand rear hitch support |

| 2 | AA88314 | Rear hitch link support |

| 1 | AA88326 | Rear hitch support |

| 2 | JD5921 | Reflective yellow label |

| 4 | N137598 | Heavy-duty spring pin |

| 2 | N280120 | Pin fastener |

| 1 | R106661 | Special cap screw |

| 1 | R110306 | Drawbar strap |

| 1 | R110309 | Plate |

| 1 | R156614 | Special cap screw |

| 1 | R26511 | Special headed pin |

| 15.2-m (50-ft)/18.3-m (60-ft) 1890 or N560F – Bulk hose, brackets, and hardware | ||

| Quantity | Part number | Description |

| 4 | 14M7296 | Hex flange nut |

| 2 | 19M7785 | Flanged screw |

| 4 | 19M7835 | Flanged screw |

| 2 | A106629 | Primary hoses retention link chain |

| 2 | AA90048 | Strap |

| 1 | AA92182 | Bracket |

The field hitch option is ordered with the cart. If this is ordered appropriately, no additional parts are needed.

Order AA79503 hitch kit, in addition to the parts list below:

| 6615 - Platform support assembly | ||

| Quantity | Part number | Description |

| 4 | 14M7291 | Hex flange nut |

| 8 | 14M7299 | Hex flange nut |

| 8 | 19M7790 | Screw |

| 2 | 19M7793 | Flanged screw |

| 2 | 19M7794 | Flanged screw |

| 2 | A63426 | Channel – rear stair support for 12,333.7-L (350-bu) tow-behind (TBH) |

| 2 | A63726 | Strap – stair support link for 12,333.7-L (350-bu) TBH |

| 1 | AA48188 | Bracket – stair support for 12,333.7-L (350-bu) TBH |

| 6620 - Dual fan rear hitch | ||

| Quantity | Part number | Description |

| 26 | 14M7299 | Hex flange nut |

| 17 | 14M7300 | Nut |

| 4 | 19M7789 | Screw |

| 4 | 19M7790 | Screw |

| 10 | 19M7791 | Flanged screw |

| 4 | 19M7813 | Flanged screw |

| 4 | 19M7814 | Screw |

| 4 | 19M7894 | Screw |

| 10 | 19M7895 | Flanged screw |

| 1 | 19M8100 | Hex head screw |

| 2 | 19M8180 | Screw |

| 1 | 24M7242 | Washer |

| 1 | A107730 | Fan-mounting bracket |

| 1 | A75174 | Bowtie clip |

| 2 | A99215 | Plate (fan bottom mount tow-behind [TBH]) |

| 1 | AA48323 | Rear hitch stair support bracket |

| 1 | AA83311 | Premium bolt-on hitch |

| 1 | AA90137 | High-capacity hitch |

| 2 | AA90143 | Rear hitch support |

| 1 | AA91220 | Dual fan mount support |

| 1 | PM01512 | Pin fastener |

| 2 | 14M7396 | Self-locking hex flange nut |

| 2 | 19M7867 | Flanged screw |

| 1 | A90559 | Plate (seven-pin TBH flow through) |

| 1 | AA76512 | Wiring harness |

| 2 | H224073 | Heavy-duty tie band |

Pre-delivery instructions (PDI) to reference:

ProSeries Openers

ProSeries OpenersProSeries Openers are in base equipment on all 1890 and N500F Separate Fertilizer Placement (SFP), 1990 Central Commodity System (CCS™), and 1590 Air Drills.

On the 1890 models, the single-disk openers are on 190-mm (7.5-in.) or 254-mm (10-in.) row spacing. On 15.25-m (50-ft) and 18.3-m (60-ft) 1890 models, the 190-mm/380-mm (7.5-in./15-in.) or 254-mm/508-mm (10-in./20-in.) dual-row spacing feature is in base equipment. The single-disk openers provide consistent and accurate seed placement.

The ProSeries Openers are gang mounted and are hydraulically raised and lowered. The hydraulic downforce system also offers a wide range of downforce settings for the openers.

Active hydraulic downforce pressure valve

Active hydraulic downforce pressure valveThe active hydraulics:

The down pressure:

NOTE: For additional ballast in hard-to-penetrate conditions, tractor suitcase weights may also be added to the mainframe and wings to obtain maximum down pressure per opener.

The ProSeries Openers:

Growers that may be interested in upgrading their current 90 Series Openers to the ProSeries Openers can do this by ordering a ProSeries performance upgrade kit.

Two kit offerings are available for seed openers, a two row (AA98693) and eight row (AA97392) kit. The breakdowns are as follows:

| A105410 | Deflector, seed firmer tab | 2 pc |

| A107506 | Washer, special | 8 pc |

| A109343 | Seed boot, left hand | 1 pc |

| A109344 | Seed boot, right hand | 1 pc |

| A110307 | Closing arm spring, left hand | 1 pc |

| A110308 | Closing arm spring, right hand | 1 pc |

| A31869 | Locknut | 2 pc |

| AA88056 | Press wheel assembly | 2 pc |

| E55662 | Nut, 3/8 | 8 pc |

| N280653 | Washer | 2 pc |

| N283804 | Opener disk | 2 pc |

| N283976 | Nut, U-nut | 2 pc |

| N283308 | Screw, flange | 2 pc |

| 03H2070 | Bolt, round head | 8 pc |

| 19M7720 | Screw, hex | 2 pc |

| A105392 | Spiked seed closing wheel | 2 pc |

| A97699 | Instructions, dealer download | 1 pc |

| A105410 | Deflector, seed firmer tab | 8 pc |

| A107506 | Washer, special | 32 pc |

| A109343 | Seed boot, left hand | 4 pc |

| A109344 | Seed boot, right hand | 4 pc |

| A110307 | Closing arm spring, left hand | 4 pc |

| A110308 | Closing arm spring, right hand | 4 pc |

| A31869 | Locknut | 8 pc |

| AA88056 | Press wheel assembly | 8 pc |

| E55662 | Nut, 3/8 | 32 pc |

| N280653 | Washer | 8 pc |

| N283804 | Opener disk | 8 pc |

| N283976 | Nut, U-nut | 8 pc |

| N283308 | Screw, flange | 8 pc |

| 03H2070 | Bolt, round head | 32 pc |

| 19M7720 | Screw, hex | 8 pc |

| A105392 | Spiked seed closing wheel | 8 pc |

| A117632 | Instructions, ProSeries | 1 pc |

ProSeries seed opener kit

ProSeries seed opener kitNOTE: Kits are subject to change.

| Key Specs | 1890-no-till-air-drill Current Model |

|---|---|

| Working widths | 9.14 m 30 ft |

| Spacing | 19.05, 25.4 cm 7.5, 10 in. |

| Number of ranks | two |

| Openers | Style Single disk-beveled edge Rank lock-up Yes Diameter 45.72 cm 18 in. Down pressure Hydraulic |

| Sizes | |

| Working widths | 9.14 m 30 ft |

| Spacing | 19.05, 25.4 cm 7.5, 10 in. |

| Number of ranks | Two |

| Number of sections | Three |

| Dimensions | |

| Transport height | 3.63 m 11.92 ft |

| Transport width | 4.37 m 14.33 ft |

| Road clearance | 21.6 cm 8.5 in. |

| Overall length | 7.49 m 24.58 ft, in. |

| Centerframe width | |

| Weight before ballast | 7711, 6759 kg 17000, 14900 lb |

| Available ballast | 1386 (28+14 x 100) kg 2800 (28+14 x 100) lb |

| Frame | Cross members 102 x 152 mm 4 x 6 in. End tubes 51 x 152 mm 2 x 6 in. Hitch 76 x 152 mm 3 x 6 in. |

| Clearance from rank to rank | 133.99 cm 52.75 in. |

| Centerline of mainframe wheel support tube to centerline of wing wheel support tubes | |

| From ground to platform | |

| From ground to top of lid | |

| From ground to top of lights | |

| From ground to top of safety rail | |

| Lateral frame clearance, opener to opener | |

| Tires | |

| Mainframe standard | (8) 11L-15, 10PR |

| Mainframe bolt pattern | |

| Wings standard | (4) 11L-15, 8PR |

| Wings bolt pattern | |

| Centerframe tires and wheels | |

| Wheel spacing, center frame | |

| Wing tires and wheels | |

| Openers | |

| Style | Single disk-beveled edge |

| Rank lock-up | Yes |

| Disk | Diameter 45.72 cm 18 in. Angle 7 degree (angle) |

| Down pressure | Style Active hydraulic-patented Hydraulic |

| Depth control | Description Gauge wheel beside disk Gauge wheel size 11.43 x 40.64 or 7.62 x 40.64 cm 4.5 x 16 or 3 x 16 in. Range 1.27 to 8.89 cm 0.5 to 3.5 in. Increments 0.64 cm 0.25 in. |

| In-Furrow press wheel | Material Rubber on plastic wheel Packing force 5 to 45 lb 2.3 to 21 kg Standard |

| Furrow closing | Description Trailing wheel on 20-degree vertical angle, 7-degree horizontal angle Size 2.54 x 30.48 cm 1 x 12 in. Material Cast iron Down force 26 to 43 lb 12 to 20 kg Standard |

| Double-Shoot capable | |

| Equipment compatibility (at 1.5 in. seeding depth and 8 mph) | |

| Tractor drawbar power required, 10-in (25.4 cm) models | |

| Tractor drawbar power required, 15-in (38.1 cm) models | |

| Tractor drawbar power required, 7.5-in (19.1 cm) models | |

| Seed Metering | |

| Crops | |

| Description | |

| Max Volumetric Seeding Rates - Barley | |

| Max Volumetric Seeding Rates - Milo/Sorghum | |

| Max Volumetric Seeding Rates - Oats | |

| Max Volumetric Seeding Rates - Rice | |

| Max Volumetric Seeding Rates - Soybean | |

| Max Volumetric Seeding Rates - Wheat | |

| Metering Drive Type | |

| Seed Storage | |

| Blower | |

| Blower drive type | |

| Distribution hose size | |

| Seed Distribution | |

| Tank Description | |

| Tank Fill Screen | |

| Tank Scales | |

| Total Tank Capacity | |

| Type | |

| Tractor requirements | |

| Hydraulic Power Beyond | |

| Minimum electrical capacity | |

| Minimum hydraulic capacity | |

| Minimum number of SCV's |