We are hiring! Run with Riesterer and Schnell: Apply Today

We are hiring! Run with Riesterer and Schnell: Apply Today

Search

Choose a Location

| Previous 9 Series models | New 0 Series models | |

| 449 | → | 440E |

| 459E | → | 450E |

| 459 | → | 450M |

| 459 Silage Special | ||

| 469 | → | 460M |

| 469 Silage Special | ||

| 469 Premium | → | 460R |

| 559 | → | 550M |

| 559 Silage Special | ||

| 569 | → | 560M |

| 569 Silage Special | ||

| 569 Premium | → | 560R |

| Baler option | Applicable models |

E = Economy

| 440E and 450E |

M = Standard

| 450M, 460M, 550M*, and 560M |

R = Premium

| 460R and 560R |

*NOTE: The 550M Round Baler will only be available in dry hay and silage configurations.

0 Series Balers have implemented specification levels for all models in the baler lineup similar to what was done when the 459E was introduced. Pickup options will remain the same for the new models equivalent specification. The precutter pickups will have the same MegaWide™ Plus pickups that will be offered in mid specification (M) or the premium specifications (R) balers.

The 0 Series Round Baler family welcomes the first, John Deere, North-American built precutter. This feed system in front of these machines is the MegaWide HC2. The MegaWide Plus name is known as the industry-leading feed system since its introduction with the 7 Series Balers. John Deere continues that legacy with the 0 Series. Proven designs of the MegaWide were maintained and improvements were made to key components to gain significant capacity.

The MegaWide™ HC2 will only be available in a precutter configuration (available on the 450M, 460M, 460R, 560M, and 560R models):

The MegaWide HC2 has the same 2.2-m (7.22-ft) MegaWide Plus pickup from the 9 Series. Dry hay and silage 0 Series configurations will also have the MegaWide Plus pickup.

Before the introduction of the MegaWide HC2 , the cam-clutch protection for the driveline was only available on the 9 Series Premium Balers. It is in the base for the MegaWide HC2 precutter configurations. This driveline pushes the limitations of the baler and the MegaWide HC2 system by offering the best machine protection John Deere can provide.

Another feature brought over from the 9 Series Premium Balers and being offered on the 0 Series is the grease banks. All daily greasing can be done from the ground in one central location.

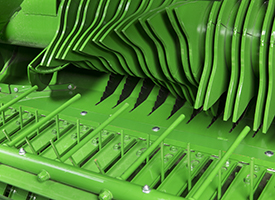

MegaWide HC2 roller baffle and MegaWide Plus roller baffles

MegaWide HC2 roller baffle and MegaWide Plus roller bafflesThe roller baffle on the MegaWide HC2 doubled in size from the MegaWide Plus from 10.2-cm (4-in.) to 20.3-cm (8-in.) diameter to allow for increased speeds and performance in larger windrows.

The 450M, 460M, 460R, 560M, and 560R Balers that can be configured with the MegaWide HC2 feed system will have the same flare-to-flare pickup width of 2.2 m (7.21 ft). This 2.2-m (7.21-ft), flare-to-flare, width on 1.22-m (4-ft) balers is only a feature of the MegaWide HC2 feed system.

Primary rotor relationship to knives – front position

Primary rotor relationship to knives – front position Primary rotor from bale chamber

Primary rotor from bale chamberThe primary rotor is only available on the MegaWide HC2 and is located directly behind the MegaWide pickups.

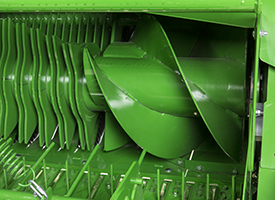

Fast-pitch augers on the primary rotor

Fast-pitch augers on the primary rotorIndustry-exclusive, fast-pitch augers have been placed on the primary rotor to move dry hay and silage past the transition points to avoid plugging.

MegaWide HC2 secondary rotor from bale chamber

MegaWide HC2 secondary rotor from bale chamberThe secondary rotor is another component on the feed system that was re-designed from the MegaWide Plus feed system to handle the increased demands of the high-capacity system.

A third drive roll is another feature that will only be offered with the MegaWide HC2 feed system.

All MegaWide HC2 feed systems will have silage components to limit maintenance and prevent crop build up on belts.

All 0 Series Balers use alpha-numeric identifiers for the model names:

The MegaWide HC2 can be ordered on mid specification (M) and premium specification (R) balers.

R specification balers will have the premium pickup with improved internal components that are covered under the 2-year/12,000-bale premium warranty

M specification balers and pickups will not contain premium baler components – exception for this is the MegaWide HC2 feed system will have the premium cam clutch for the driveline and grease banks.

For more information about the model specifications, see the chart below:

| Baler option | Applicable models |

E = Economy

| 440E and 450E |

M = Standard

| 450M, 460M, 550M*, and 560M |

R = Premium

| 460R and 560R |

*NOTE: The 550M is only available in dry hay and silage configurations.

New Holland, Roll-Belt, and CropCutter are trademarks of CNH Global N.V. and its subsidiaries.

Drop floor – if the baler exceeds capacity and plugs, the MegaWide HC2 can lower the knife floor from the cab of the tractor to easily feed the plug into the chamber.

Increased torque – the MegaWide HC2 feed system required an additional drive configuration to power the primary rotor and to meet the capacity goals.

MegaWide HC2 feed systems will not have the adjustable crank handle for the pickup.

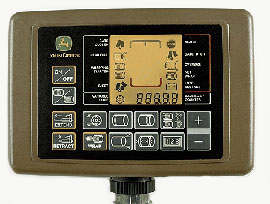

BaleTrak Pro monitor-controller

BaleTrak Pro monitor-controllerThe BaleTrak Pro monitor-controller is included with the automatic electric tie option and the Edge-to-Edge option on the 450E Baler. The monitor sounds an alarm for near-full, full, and oversized bales.

The audible level of the monitor can be adjusted.

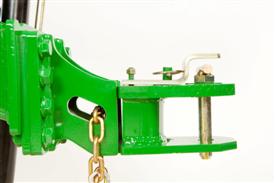

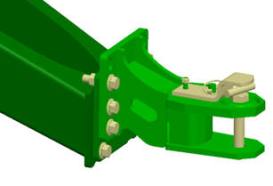

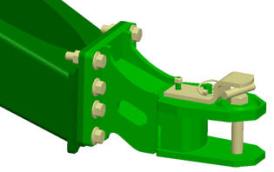

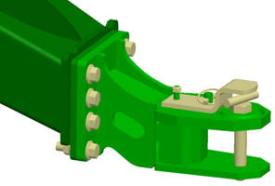

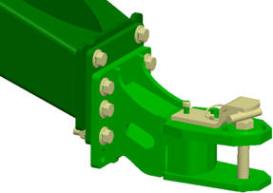

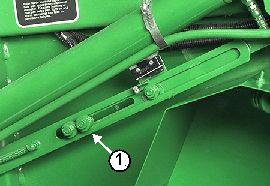

Side view of adjustable hitch

Side view of adjustable hitch Front view of adjustable hitch

Front view of adjustable hitchThe 9 Series Round Balers came standard with an adjustable hitch and this feature will continue to be in base with the 0 Series Round Balers. This feature allows the hitch height to be adjusted to optimize crop-feeding performance. Due to the wide array of tractor tire sizes and drawbar heights, hitch adjustment may be necessary to get the proper feed opening of the baler. The adjustable hitch eliminates the need for the 51-mm (2-in.) thick tractor drawbar kit (AE57344) because it has a wider opening.

Benefits of the adjustable hitch:

All eight bolts must be used when adjusting the hitch. There are four different positions as shown below:

Position 1 (top) - regular and MegaTooth™ pickups

Position 1 (top) - regular and MegaTooth™ pickups Position 2

Position 2 Position 3 (factory setting) - MegaWide Plus and MegaWide HC2

Position 3 (factory setting) - MegaWide Plus and MegaWide HC2 Position 4 (bottom)

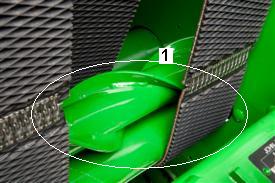

Position 4 (bottom)Also standard on all 0 Series Round Balers, except the 450E, is the drawbar flap. This helps to eliminate hay from getting caught on the hitch of the baler. The drawbar flap is designed to allow the operator to remove or attach the flap without having to unhook the baler from the tractor.

Drawbar flap

Drawbar flap Drawbar flap installed on baler

Drawbar flap installed on baler Tractor-baler automation display screen

Tractor-baler automation display screen

Tractor-baler automation allows for easier operation and reduced operator fatigue after all-day operation. This function is only compatible with model year 2010 or newer John Deere 6030/7030 Premium Tractors or model year 2011 or newer 6R/7R/8R Tractors that are GreenStar™- or AutoTrac™-ready.

6030 Premium Tractors include: 6230 Premium, 6330 Premium, and 6430 Premium Tractors.

7030 Premium Tractors include: 7130 Premium, 7230 Premium, 7330 Premium, 7430 Premium, and 7530 Premium Tractors.

Activation fees for tractor-baler automation is no longer needed for the tractor and baler.

All tractors must be ISOBUS compatible. All balers must have a push bar when operating in tractor-baler automation mode. Tractor-baler automation will not work with the Plus2 Round Bale Accumulator.

NOTE: 6R Series Tractors can still be ordered non-ISO compatible. Please order the GreenStar-ready wiring harness package or AutoTrac-ready wiring harness package to make the 6R Tractor ISO compatible. Model year 2015 and newer Final Tier 4 6R Series Tractors must be ordered AutoTrac-ready from the factory in order to work with tractor-baler automation.

NOTE: Premium Round Balers can run on any tractor that is ISOBUS compatible (or made ISOBUS compatible with wiring harness); however, tractor-baler automation will only work on the tractors/features listed.

NOTE: Having the ISOBUS coupler does not necessarily mean that the tractor is GreenStar-ready.

There are two levels of tractor-baler automation.

460M MegaWide Plus pickup

460M MegaWide Plus pickupA MegaWide Plus pickup is available on 440E, 450M, 550M, and 560M Round Balers. It is base equipment on the 450M Silage, 550M Silage, 460M, 460M Silage, and 560M Silage Balers. The MegaWide Plus pickup is also incorporated into the new MegaWide High Capacity and Cutting (HC2) high-capacity precutter feed system.

0 Series Balers have implemented specification levels for all models in the baler lineup, similar to what was done when the 459E was introduced. Pickup options will remain the same for the new models equivalent specification. The precutter pickups will have the same MegaWide Plus pickups that will be offered in mid specification (M) or the premium specification (R) balers.

MegaWide Plus pickups make baling easier, especially in wide or windblown windrows, and increases productivity; more hay volume means more bales per hour.

MegaTough pickup teeth

MegaTough pickup teethMega and MegaTough pickup teeth are base equipment:

Toothbars on 1.5-m (5-ft) baler

Toothbars on 1.5-m (5-ft) balerThe 1.2-m (4-ft) balers use a full-length, reinforced toothbar design.

The 1.5-m (5-ft) balers use a heavy, C-channel construction. The pickup toothbars are divided into two half-sections that mount to a center spider for increased strength and even crop feeding.

Roller baffle

Roller baffleAvailable only on the MegaWide Plus pickup, the patented roller baffle is self-adjusting and produces smoother crop flow across the pickup. The roller also improves crop pickup in small windrows and prevents roll ahead of crop.

When combined with the MegaWide Plus pickup, this feeding system allows increased ground speed with less chance of plugging for increased productivity in all field conditions.

Spiral rotor

Spiral rotor Auger and rotor feed system

Auger and rotor feed systemThe MegaWide Plus pickup uses a rotor-feeding assembly, which mounts behind the pickup for smooth and even crop flow into the bale chamber.

Rotor stripper

Rotor stripperRotor strippers allow crop to be lifted from the rotor teeth into the chamber without cutting or wrapping the crop.

Cut-out clutch protection and feeder-drive chain

Cut-out clutch protection and feeder-drive chainThe MegaWide Plus pickups and spiral rotor are chain-driven for positive bale starts with cutout clutch protection. The pickup is being driven off the drive roll and bypasses the starter roll. This will allow for reduced wear and breakage of the starter roll chain.

Semi-pneumatic gauge wheel

Semi-pneumatic gauge wheelSemi-pneumatic gauge wheels provide smooth ground gauging over uneven terrain and protection to the pickup.

The pickup float springs are positioned for excellent flotation.

Adjustable crank handle

Adjustable crank handleThe adjusting crank positions the pickup to the desired operating height to match crop or field conditions.

An optional hydraulic pickup lift cylinder is available as an attachment.

Bale-starting diagram

Bale-starting diagramAs the hay enters the forming chamber from the pickup, belts immediately turn the hay to form a tight, dense core.

Incoming hay then feeds between the bale and the lower gate roll. Hay is tightly compressed into smooth, dense layers as it enters the bale.

Chaffing is greatly reduced to prevent loss and retain hay quality in the bale.

Full-sized bale in bale chamber

Full-sized bale in bale chamberThe idler arm rises with bale growth, forcing oil from the hydraulic cylinder through a pressure-relief valve to maintain uniform bale density throughout the bale-forming process.

Staggered belts

Staggered beltsJohn Deere's 178-mm (7-in.) wide diamond-tread design ensures fast bale starts and grips the bale to prevent slippage and reduce chaffing. The treads are self-cleaning to reduce carryover. The belts are staggered to reduce the loss of fine material and are closely spaced to contain the hay for fast, easy starts.

The belts enclose 91 percent of the bale width to reduce loss of fine material and retain hay quality.

The staggered belt roll design enables any loose hay under or behind the belts to be returned to the pickup and into the baler. This design helps to prevent buildup at the front of the baler, which could cause hay loss and belt or splice damage.

DiamondTough triple-weave belts

DiamondTough triple-weave belts

Every baler in the 0 Series Family uses DiamondTough belts. Belts are constructed using a patented triple-weave process of nylon and polyester materials.

They have the strength to handle heavy shock loads and help maintain consistent belt length.

The DiamondTough belts are more puncture and tear resistant than other belts on the market and provide improved belt life and reliability.

Plate-type splices

Plate-type splices

All of the 0 Series Balers use the plate-type fasteners.

This closed-loop design uses a plate fastener with pre-assembled rivets that lock the fasteners into the belt, providing a powerful vice-type grip on the belt.

Manual bale size adjustment

Manual bale size adjustmentOn the 440E Round Baler with hydraulic double-twine option, the near-full bale size warning can be adjusted by moving the nut (1) in the slot to match harvest requirements.

BaleTrak Pro bale size adjustment

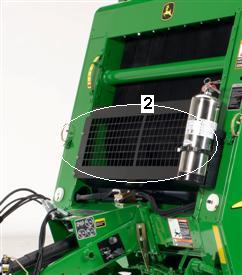

BaleTrak Pro bale size adjustment MegaWide™ High Capacity and Cutting (HC2) system monitor

MegaWide™ High Capacity and Cutting (HC2) system monitorThe bale size on 450M, 450E with automatic electric tie, 550M, 460M, and 560M Round Balers can be adjusted from the operator's station with the BaleTrak™ Pro monitor-controller by pressing symbol 2, then pushing the +/- symbol.

Staggered roller-auger kit

Staggered roller-auger kit

A silage-configuration baler allows the producer to put up silage hay. A silage configuration machine does not offer a precutter. There are three major components to a silage configuration baler: a staggered roller-auger kit (1), a starter roll-scraper knife, and a screen (2). The powered auger sits above the staggered roll on the baler to help keep wet hay from traveling up the belts and reduce buildup on the roll. The screen is bolted on the front of the baler as a safety feature. The knife/scraper is mounted in front of the starter roll to help prevent wrapping of wet crop on the starter roll.

The silage kit is offered as a bundle for field installation if the baler is not ordered as a silage-configuration machine from the factory. Attachment BE32442 is for 1.22-m (4-ft) wide machines and BE32443 is for1.52-m (5-ft) wide machines.

Also offered is a high-moisture kit. This kit does not include the same components that are on the silage-configuration balers. It offers the starter roll-scraper knife but does not include the staggered roll-auger kit. Attachment BE23828 is for 1.22-m (4-ft) machines and BE23829 is for 1.52-m (5-ft) machines.

Starter roll knife and screen

Starter roll knife and screen

Base equipment on: 450M Silage, 550M Silage, 460M Silage, 560M Silage, 450M Precutter, 460M/R Precutter and 560M/R Precutter.

Auxiliary take-up rolls

Auxiliary take-up rolls

Auxiliary take-up rolls prevent belt crossover and flipping in wet conditions. This roll is base equipment on all silage and precutter configuration balers. It also comes with the bale ramp bundle on the 440E and 450E Balers.

The 0 Series Round Baler family welcomes the first, John Deere, North-American built precutter. This feed system in front of these machines is the MegaWide HC2. The MegaWide Plus name is known as the industry-leading feed system since its introduction with the 7 Series Balers. John Deere continues that legacy with the 0 Series. Proven designs of the MegaWide were maintained and improvements were made to key components to gain significant capacity.

The MegaWide™ HC2 will only be available in a precutter configuration (available on the 450M, 460M, 460R, 560M, and 560R models):

The MegaWide HC2 has the same 2.2-m (7.22-ft) MegaWide Plus pickup from the 9 Series. Dry hay and silage 0 Series configurations will also have the MegaWide Plus pickup.

The gull wing doors from the 9 Series Premium Balers have been removed. All M- and R-specification 0 Series Balers will have the same stamped, steel door design.

Grease bank

Grease bank

Standard on premium round balers is a factory-installed grease bank. This allows the operator to only have to grease eight zerks (four on each side of the baler) for grease zerks that were hard to reach on previous models. The operator will still have to grease the driveline and some other components on the baler.

NOTE: The grease bank will also be found on all 0 Series precutter configuration balers, M and R specification.

CommandCenter™ display with third bale shape sensor

CommandCenter™ display with third bale shape sensor

The 460R Premium and 560R Premium offer the producer a third bale-shape sensor that can be turned on or off. This will allow the operator to make consistent, square-shouldered bales since they can now see how the center of their bales are forming.

Connection of ISO monitor wiring harness to the tractor

Connection of ISO monitor wiring harness to the tractor Controller on baler

Controller on balerThe ISOBUS system offered on the premium round balers allows the operator to use the latest technology when baling. They can utilize their GreenStar™ 2600, GreenStar 2630, GreenStar 1800, or certain R-Series CommandCenter displays as their baling monitor and can switch between tractors without having to take the display with them. All information for the baler is stored on the controller.

A two-year or 12,000-bale warranty comes standard on 460R Premium and 560R Premium Round Balers only. Please see full product warranty for more details.

Compare the specifications of up to 4 models

| Key Specs | 460r-megawidehc-round-baler Current Model |

|---|---|

| Belts-other - width | 17.8 cm 7 in. |

| Density control | Hydraulic |

| Bale size indication | Electronic display on monitor |

| Regular pickup - Bars | |

| Regular pickup - Number of teeth | |

| Regular pickup - Tooth spacing | |

| MegaWide Plus pickup - Number of regular teeth | 96 |

| MegaWide Plus pickup - Number of mega teeth | 16 |

| High-capacity pickup - Number of middle teeth | 120 |

| High-capacity pickup - Number of mega teeth | Eight |

| Bale | |

| Size | Diameter 81 - 183 cm 32 - 72 in. Width 117 cm 46 in. 1.2 x 1.8 m 4 x 6 ft |

| Weight | Full-size bale in dry crop 748 kg 1,650 lb Max. allowable for silage bale 998 kg 2,200 lb |

| Baler | |

| Base weight | |

| Weight | Shipping dry - 2,950 kg 6,500 lb Shipping precutter - 3,930 kg 8,665 lb |

| Length | Gate closed 371 cm 146 in. Gate open 475 cm 187 in. |

| Height | Gate closed 279 cm 110 in. Gate open 368 cm 145 in. |

| Width | With standard tires 226 cm 89 in. With opt. tires (Hi-Flotation) 244 cm 96 in. |

| Bale forming | |

| Forming chamber | |

| Belts-other | Number Six Width 17.8 cm 7 in. Texture Diamond Tread friction surface belts DiamondTough, triple-weave, single-ply belts |

| Enclosed percent of bale surface | |

| Belt splices | |

| Density control | Hydraulic |

| Bale size indication | Electronic display on monitor |

| Bale Shape | |

| Regular pickup | |

| Type | |

| Width | |

| Drive | |

| Bars | |

| Number of teeth | |

| Tooth spacing | |

| Lift control | |

| Gauge wheels | |

| Stripper diameter | |

| MegaWide Plus pickup | |

| Type | |

| Width | Inside 155 cm 61 in. Flare 180 cm 71 in. |

| Drive | |

| Bars | |

| Number of regular teeth | 96 |

| Number of mega teeth | 16 |

| Tooth spacing | |

| Lift control | |

| Gauge wheels | Semi-pneumatic |

| Stripper diameter | |

| High-capacity pickup | |

| Type | MegaWide High Capacity and Cutting (HC |

| Width | Inside 196 cm 77 in. Flare 221 cm 87 in. |

| Drive | |

| Bars | |

| Number of middle teeth | 120 |

| Number of mega teeth | Eight |

| Tooth spacing | |

| Lift control | |

| Gauge wheels | Semi-pneumatic |

| Stripper diameter | 25.4 cm 10 in. |

| Wrapping system | |

| Control | Automatic to preset to bale size |

| Type | Standard Electric |

| Twine arms | Two |

| Twine ball capacity | Eight |

| Monitor | |

| Monitor console for tractor | ISOBUS |

| Gate closed | Symbol on monitor |

| Bale forming | ISOBUS |

| Bale size | Mechanical and digital |

| Near full bale | Audible, adjustable alert |

| Full bale | Audible, adjustable alert |

| Twine arm position Indicator | Mechanical |

| Auto wrap | Activates when bale reaches preset size |

| Oversize bale | Yes, audible and mechanical alerts |

| Surface wrap | |

| Tire size | |

| Standard | Premium - XL high-flotation 21.5L-16.1, 8 PR |

| Optional | |

| Driveline | |

| Drive protection | Premium - cut out clutch |

| PTO speed | 540 or 1,000 rpm |

| Type | Constant-velocity (CV) |

| PTO lockback collar on tractor hookup | Yes |

| PTO 60-degree free rotation | Yes |

| Tractor Requirements | |

| Minimum PTO | Dry Hay and Silage - 48 kW 65 hp MegaWide HC kW 85 hp |

| Hydraulic SCV valves | One tractor selective control valve (SCV) is required when baler is equipped with electric twine wrap. Two tractor SCVs are required when baler is equipped with hydraulic twine wrap. Three tractor SCVs are required when baler is equipped with hydraulic twine wrap and a hydraulic pickup lift. |

| Silage baler features | |

| Starter roll scraper | |

| Powered scraping auger | |

| Spirals on gate roll | |

| Pre-cutter/slicer |

Hydraulic bale ramp

Hydraulic bale ramp

Hydraulically operated bale ramps are available as optional equipment on 459, 459 Standard, 459 Silage Special, 559 Silage Special, and 559 Round Balers.

NOTE: The tractor must have a 2200-psi hydraulic system to operate hydraulic bale ramps.

Crop deflector kit

Crop deflector kit

The crop deflector kit prevents crop accumulation in the lower gate area of the baler that can keep the gate from closing. The deflector keeps crop out of the lower gate area as the bale is ejected from the bale chamber.

Variable core for balers with BaleWatch

Variable core for balers with BaleWatchThis variable core kit is for 457, 457 Silage Special, and 557 Balers equipped with the BaleWatch™ monitor.

Variable core for BaleTrak Plus or BaleTrak Pro

Variable core for BaleTrak Plus or BaleTrak ProThis variable core kit is for 67 Series Balers and 57 Series Balers equipped with the BaleTrak™ Pro and BaleTrak Plus monitor-controller.

This kit reduces hydraulic pressure for easier bale starts in difficult conditions.

BaleTrak Pro monitor-controller

BaleTrak Pro monitor-controllerA second BaleTrak Pro monitor-controller and tractor portion of the wiring harness can be ordered for installation on a second tractor, if desired:

Override switch

Override switchA manual twine-arm override switch (A) is included with the monitor wiring.

The switch allows the operator to manually wrap twine on the bale if the BaleTrak Pro monitor-controller malfunctions.

NOTES:

These parts are required to install the electric twine-wrap control module on the tractor for 447 and 547 Round Balers.

A54171 and A53254

A54171 and A53254A54171 and A53254 are for 447 and 547 Round Balers with the optional electric twine module.

BE23863

BE23863BE23863 is required to mount the electric twine control module on open-station tractor rollover protective structures (ROPS) for 447 and 547 Round Balers.

In addition to this bundle, the following brackets and hardware must be ordered through Parts.

For the electric twine control module, also order A54171 and A53254

E88560

E88560E88560 is for the electric twine control module for the 447 and 547 Round Balers.

These parts are required to install the electric twine-wrap control module on the tractor for 447 and 547 Round Balers.

A54171 and A53254

A54171 and A53254A54171 and A53254 are for 447 and 547 Round Balers with the optional electric twine module.

BE23863

BE23863BE23863 is required to mount the electric twine control module on open-station tractor rollover protective structures (ROPS) for 447 and 547 Round Balers.

In addition to this bundle, the following brackets and hardware must be ordered through Parts.

For the electric twine control module, also order A54171 and A53254

E88560

E88560E88560 is for the electric twine control module for the 447 and 547 Round Balers.

These parts are required to install the electric twine-wrap control module on the tractor for 447 and 547 Round Balers.

A54171 and A53254

A54171 and A53254A54171 and A53254 are for 447 and 547 Round Balers with the optional electric twine module.

BE23863

BE23863BE23863 is required to mount the electric twine control module on open-station tractor rollover protective structures (ROPS) for 447 and 547 Round Balers.

In addition to this bundle, the following brackets and hardware must be ordered through Parts.

For the electric twine control module, also order A54171 and A53254

E88560

E88560E88560 is for the electric twine control module for the 447 and 547 Round Balers.

These parts are required to install the electric twine-wrap control module on the tractor for 447 and 547 Round Balers.

A54171 and A53254

A54171 and A53254A54171 and A53254 are for 447 and 547 Round Balers with the optional electric twine module.

BE23863

BE23863BE23863 is required to mount the electric twine control module on open-station tractor rollover protective structures (ROPS) for 447 and 547 Round Balers.

In addition to this bundle, the following brackets and hardware must be ordered through Parts.

For the electric twine control module, also order A54171 and A53254

E88560

E88560E88560 is for the electric twine control module for the 447 and 547 Round Balers.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Drawbar shield

Drawbar shieldA drawbar shield helps to prevent windrow bunching that can occur when the drawbar contacts heavy windrows.

Fire extinguisher

Fire extinguisherA pressurized 2-1/2 U.S. gal. (9.5-L) water-type fire extinguisher can be installed on the baler.

It is recommended for hay and grass fires.

Fire extinguisher

Fire extinguisherA pressurized 2-1/2 U.S. gal. (9.5-L) water-type fire extinguisher can be installed on the baler.

It is recommended for hay and grass fires.

Seven-pin outlet kit

Seven-pin outlet kitThe seven-terminal electrical outlet is required on tractors not equipped to power the taillights and turn signals.

Convenience outlet kit

Convenience outlet kitThis convenience outlet and wiring harness can be installed in a tractor without a convenience outlet to power the monitor.

The harness is recommended for use with either the optional BaleWatch™ monitor on 457, 457 Silage Special, and 557 Round Balers, or with the BaleTrak™ Pro and BaleTrak Plus monitor-controller on 457, 457 Silage Special, 557, 467 Silage Special, 467, and 567 Round Balers.

Adapter

AdapterThis wiring harness is required to hook up electric controls with a three-terminal plug to a tractor with a two-terminal convenience outlet.

The harness is recommended to be used only with the BaleWatch™ monitor on 457, 457 Silage Special, and 557 Round Balers.

IMPORTANT: Do not use this harness with the BaleTrak™ Pro or BaleTrak Plus monitor-controller. A voltage drop may occur, resulting in lower force from the twine and surface-wrap accuators.

625 Mower-Conditioner illustrated

625 Mower-Conditioner illustratedA safety chain serves as a device to ensure the mower-conditioner stays attached to the tractor, should a drawbar or hitch pin failure occur.

The tractor must be equipped with an intermediate chain support ahead of the hitch pin.

Pressure reduction kit

Pressure reduction kitThe hydraulic pressure reduction kit is required when 435 ( -969343) and 535 ( -971693) Round Balers, equipped with a push bar, are used with a John Deere 6000 and 7000 Series Tractor or competitive tractor with hydraulic system pressure above 2500 psi.

It reduces the potential for damage to the gate cylinders due to high-pressure spikes when opening the gate on balers equipped with a push bar.

Adjustable twine guide

Adjustable twine guideAdjustable twine guides are used to move the location of the twine closer to the center of the bale.

Auxiliary take-up rolls eliminate flipping and twisting of the belts in hilly conditions.

Base Equipment: All silage special round balers.

Auxiliary take-up rolls eliminate flipping and twisting of the belts in hilly conditions.

Base Equipment: All silage special round balers.

The rearview mirrors mount to the tractor cab to improve rearward visibility.

Gathering wheels

Gathering wheelsGathering wheels aid in picking up extra-wide or wind-scattered windrows.

Gathering wheels are side mounted and spring loaded.

NOTE: Gathering wheels are not available for MegaWide™ pickups.

High-moisture kit

High-moisture kitThis kit is for use when baling high-moisture crops.

Roll scrapers, mountings, and a staggered belt roll with anti-buildup spirals reduce wrappage and crop buildup.

High-moisture kit

High-moisture kitThis kit is for use when baling high-moisture crops.

Roll scrapers, mountings, and a staggered belt roll with anti-buildup spirals reduce wrappage and crop buildup.

Lacer vice

Lacer viceUse the lacer vice for repairing failed clipper-style belt splices or for splicing broken belts. When properly used, it will allow tight, even spacing of hooks when repairing belts.

It replaces the correct number of hooks in the belt in one operation. (Order through Parts.)

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Use the sidesheet enhancement kit in extremely abrasive crops and field conditions to add additional service life to 7 or 8 Series Round Balers with worn side sheets.

4-ft-wide auger kit (shield removed for photo)

4-ft-wide auger kit (shield removed for photo)In very dry, fluffy crop conditions, this auger kit prevents crop from climbing the front of the baler belts on 458 Standard, 458, and 468 Balers.

Located on top of the front staggered belt roll, the auger is chain-driven.

This auger kit is not a replacement for the high-moisture baling kit.

Variable core for balers with BaleWatch

Variable core for balers with BaleWatchThis variable core kit is for 457, 457 Silage Special, and 557 Balers equipped with the BaleWatch™ monitor.

Variable core for BaleTrak Plus or BaleTrak Pro

Variable core for BaleTrak Plus or BaleTrak ProThis variable core kit is for 67 Series Balers and 57 Series Balers equipped with the BaleTrak™ Pro and BaleTrak Plus monitor-controller.

This kit reduces hydraulic pressure for easier bale starts in difficult conditions.

Use the sidesheet enhancement kit in extremely abrasive crops and field conditions to add additional service life to 7 or 8 Series Round Balers with worn side sheets.

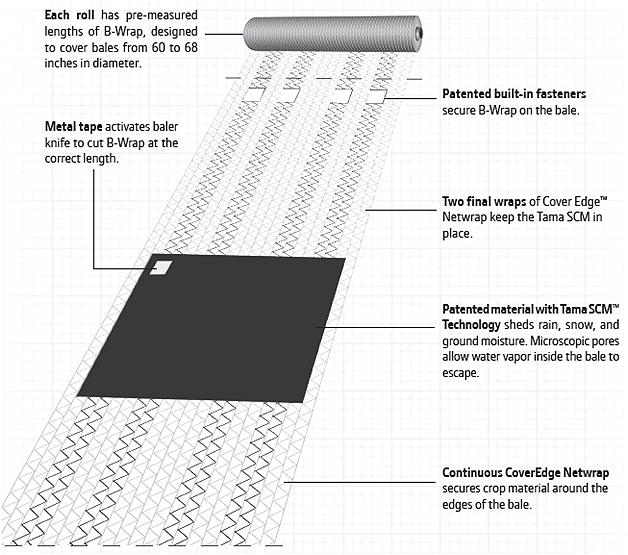

B-Wrap protects bales from rain, snow, and ground moisture

B-Wrap protects bales from rain, snow, and ground moisture

B-Wrap is applied onto bales just like net wrap, but it protects hay much better than net. B-Wrap includes a special patented material with Tama SCM Technology. It sheds rain and snow while protecting the bale from ground moisture. Plus this material has microscopic pores that let water vapor inside the bale escape. B-Wrap is the alternative to indoor storage, delivering barn-quality hay without the barn.

B-Wrap protects bale quality in all types of crops. Use B-Wrap on top quality hay, as well as straw, peanut hay, and corn stalks.

The B-Wrap kit is simple and can be dealer-installed in the field

The B-Wrap kit is simple and can be dealer-installed in the field

The B-Wrap kit is easy to install. The kit includes wiring that connects a sensor to the bale monitor and a new EPOM chip is also added to the bale monitor.

The B-Wrap kit is available for 459, 459 Silage Special, 559, 559 Silage Special, 469, 469 Silage Special, 569, and 569 Silage Special Round Balers.

This kit also works on these 7 and 8 Series Round Balers equipped for netwrap: 457, 457 Silage Special, 467, 467 Silage Special, 557, 567, 458, 458 Silage Special, 468, 468 Silage Special, 558, and 568 Round Balers. (7 and 8 Series Balers must be equipped with a speed compensation/slip clutch alert kit (BE32317). This speed compensation kit was standard equipment on some later 8 Series Balers. Balers with this kit have sensors on the slip clutch.)

A roll of John Deere B-Wrap

A roll of John Deere B-Wrap

A roll of B-Wrap looks and weighs similar to a roll of net, and B-Wrap loads into John Deere round balers exactly like net.

B-Wrap is designed for bales 60- to 68-in. in diameter. A roll of B-Wrap for 5-ft balers has 35 premeasured portions, enough to wrap exactly 35 bales. A roll of B-Wrap for 4-ft balers will wrap exactly 45 bales.

Balers with the B-Wrap attachment can switch between net wrap or B-Wrap

Balers with the B-Wrap attachment can switch between net wrap or B-Wrap

B-Wrap works in round balers much like net wrap. The B-Wrap kit allows a baler to use either B-Wrap or net. Switching between net and B-Wrap will take less than five minutes. Simply switch rolls, properly thread the new wrap into the baler, and then change bale monitor settings.

Here’s how B-Wrap works in the baler. When a bale reaches the maximum size programmed into the monitor, the operator stops forward travel and wrapping begins. The first length of B-Wrap is John Deere COVER-EDGE™ Net Wrap. John Deere COVER-EDGE goes right over the edge or the bale, pulling in loose crop material, giving the bale a solid, weather-resistant shape.

The next length of B-Wrap includes the patented material with Tama SCM technology. It sheds rain and snow, and protects bales from ground moisture. The final length covering a bale is two more wraps of John Deere COVER-EDGE Net. This securely holds the weather resistant Tama SCM in place.

Roll of B-Wrap showing the net wrap and patented material

Roll of B-Wrap showing the net wrap and patented material

Metal tape on the SCM activates the knife, cutting the B-Wrap at exactly the predetermined length. The

operator then backs the baler up about 10 feet and ejects the bale. Built-in fasteners keep B-Wrap in place during storage.

Built-in fasteners secure B-Wrap to the bale

Built-in fasteners secure B-Wrap to the bale

Limitations of B-Wrap:

Adjustable twine guide

Adjustable twine guideAdjustable twine guides are used to move the location of the twine closer to the center of the bale.

XL tire

XL tireThe 21.5-16.1 XL high-flotation tires may be installed on balers equipped with a MegaWide™ or MegaWide Plus pickup to improve ride and decrease ground compaction.