We are hiring! Run with Riesterer and Schnell: Apply Today

We are hiring! Run with Riesterer and Schnell: Apply Today

Search

Choose a Location

Single-point hydraulic connection on the 600R Loader

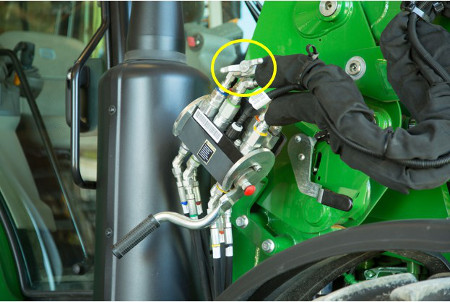

Single-point hydraulic connection on the 600R LoaderThe R-Series Loaders feature a single-point hydraulic connection that saves the operator time when attaching or detaching the loader. This feature also incorporates the connection point for any electrical needs as well as the hydraulic lockout valve. With all hydraulic and electrical connections in one location, installation is quickly completed with the pull of a handle.

NOTE: Before disconnecting the hydraulic connection between the loader and the tractor, it is necessary to release the hydraulic pressure.

Single-point hydraulic connection (open)

Single-point hydraulic connection (open) Single-point hydraulic connection (closed)

Single-point hydraulic connection (closed) 600R Loader with concealed oil lines

600R Loader with concealed oil lines

The R-Series Loaders have been redesigned to route the oil lines and hydraulic lines through the boom arm and the torque tube. This internal routing ensures better protection of the lines from external damage and improves the overall appearance of the loader.

600R Loader (side view)

600R Loader (side view) 600R Loader (angle view)

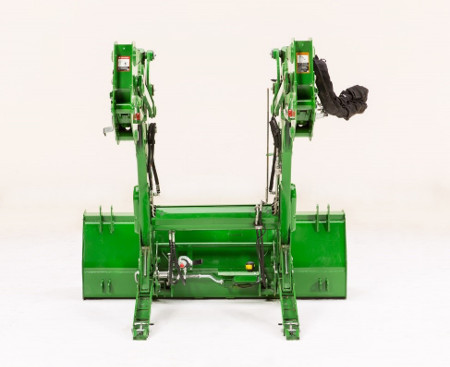

600R Loader (angle view) Rear view of 600R Loader

Rear view of 600R LoaderR-Series Loaders are even easier to attach and detach due to the automatic mast latch system. This feature provides efficiency to operations that require frequent loader parking. The automatic mast latch system is a mechanical lever that allows operators to remove or attach the loader with one trip out of the cab. The ease and convenience provided by the automatic mast latch system provides improvement to operation uptime.

Automatic mast latch lever

Automatic mast latch lever Visual lock/unlock indicator

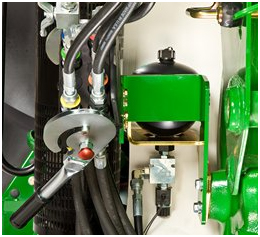

Visual lock/unlock indicator Hydraulic shut-off valve on R-Series Loader

Hydraulic shut-off valve on R-Series LoaderThe R-Series Loaders come equipped with a hydraulic shut-off valve to improve servicabiity. When conducting brief service to the loader, close the hydraulic shut-off valve to ensure the loader does not move while operating under the equipment. This feature promotes a safe way to conduct brief maintenance without having to use support stands or removing the loader completely.

600R Loader working with 6120M Tractor

600R Loader working with 6120M Tractor

The MSL R-Series Loaders utilize a false rod cylinder to improve bucket performance. This bucket cylinder is designed with a smaller displacement of oil required on the head end of the cylinder, which allows the cylinder to function more quickly, decreasing operation cycle time. With the false rod cylinder design, loader applications can work more quickly and efficiently.

False rod cylinders on 600R Loader

False rod cylinders on 600R Loader 600R Loader on a 6120M Tractor

600R Loader on a 6120M TractorThe R-Series Loaders provide several options to enhance operator experience and productivity in the field. Individual options can be ordered to fit an operation’s unique set of needs. Some of the available loader options include:

600R Loader with light-emitting diode (LED) lights

600R Loader with light-emitting diode (LED) lightsTo further enhance visibility, the 600R Loader has the option to include LED lights. With LED lights mounted onto each side of the loader boom, performing loader applications in variable operating conditions is made easier. Pairing the loader LED light option with an LED light package on the 6110M or 6120M Tractor will provide unmatched visibility to enhance operator experience during any task.

Two-button activation for hydraulic remote implement latch

Two-button activation for hydraulic remote implement latchThe hydraulic remote implement latch allows implements to be changed quickly and efficiently. An operator can activate the device from the cab by simultaneously pressing the two buttons installed on the right-hand side of the operator’s station. Switching from one attachment to the next can now be accomplished quickly with limited movements of the loader and without leaving the operator’s seat.

Electronic loader joystick

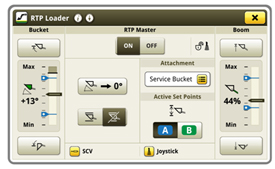

Electronic loader joystickThe second generation of industry-exclusive RTP Gen 2 with ESL provides a practical solution for operators with daily, repetitive, material handling needs. RTP allows the operator to set different position points for the loader with the flick of the wrist, activating the detent in electronic joysticks. With the second generation of RTP, operators can set application profiles rather than entering position points each time an application is in use. RTP Gen 2 with ESL removes repetition and fatigue from loader applications.

600R Loader working with a 5100R Tractor

600R Loader working with a 5100R TractorThe loader suspension system improves operator comfort and loader efficiency during loader operation. This system is easily activated by the operator from the cab. When activated, the loader suspension system absorbs the shock providing a smoother ride in the cab as well as reducing material loss from the bucket.

Compare the specifications of up to 4 models

| Key Specs | 680r-loader Current Model |

|---|---|

| Maximum lift height (A) | 4480 mm 176 in. |

| Lift capacity at full height | Measured at pivot (U) 2453 kg 5408 lb |

| Boom breakout force | Measured at pivot (Y) 3411 kgf 7520 lbf |

| Bucket rollback force capacity | At ground-level line (ZZ) 4336 kgf 9559 lbf |

| Clearance at full height - bucket dumped (C) | 3465 mm 136 in. |

| Dump angle, degrees (E) | 60 degree (angle) |

| Rollback angle, degrees (G) | 48 degree (angle) |

| Tractor | |

| Model | 6175R/M, 6195R/M, 6215R |

| Front tire | 600/70R28 |

| Rear tire | 650/85R38 |

| Front axle configuration | MFWD |

| Wheelbase | 2800 mm 110 in. |

| Pump capacity | 114 L/min 30.1 gpm |

| Rated pressure | 200 bar 2900 psi |

| Loader | |

| Base weight | 1808.2 kg |

| Leveling configuration | Mechanical Self Leveling (MSL) |

| Bucket used | Heavy-duty grapple 2450 mm Heavy-duty grapple 96 in. |

| Bucket weight | 375 kg 826 lb |

| Lift capacity at full height | Measured at pivot (U) 2453 kg 5408 lb Measured at 800 mm ahead of pivot (V) 2431 kg 5359 lb |

| Lift capacity at 59 in. (1500 mm) | Measured at pivot (W) 2989 kg 6590 lb Measured at 800 mm ahead of pivot (X) 2821 kg 6219 lb |

| Boom breakout force | Measured at pivot (Y) 3411 kgf 7520 lbf Measured at 800 mm ahead of pivot (Z) 3001 kgf 6616 lbf |

| Bucket rollback force capacity | At maximum height (VV) 3117 kgf 6872 lbf At 59-in. (1500-mm) lift height (XX) 4486 kgf 9890 lbf At ground-level line (ZZ) 4336 kgf 9559 lbf |

| Dimensions | Maximum lift height (A) 4480 mm 176 in. At full height - bucket level(B) 4240 mm 167 in. At full height - bucket dumped (C) 3465 mm 136 in. |

| Overall length (I+F), ft (m) | 5.5 m 17.9 ft |

| Overall height in carry position (J) | |

| Digging depth (H) | 96 mm 5 in. |

| Reach | At maximum height (D) 1346 mm 53 in. At ground level - bucket level (F) 2931 mm 115 in. |

| Bucket angle | Dump angle, degrees (E) 60 degree (angle) Rollback angle, degrees (G) 48 degree (angle) Dump angle, ground 117 degree (angle) |

| Cycle times | Loader raise, seconds 4.19 seconds Loader lower, seconds 2.89 seconds Bucket dump, seconds 1.81 seconds Bucket rollback, seconds 1.81 seconds |

Heavy-duty bucket (shown with grapple)

Heavy-duty bucket (shown with grapple)

The high-volume bucket is intended for use with lighter-density high-volume materials. The bucket capacity makes this an effective tool for handling snow, wood shavings, and other loose materials.

Materials bucket

Materials bucket

Materials buckets may be used for loading dirt, gravel, feed, and light materials as well as scraping, digging, and other general-purpose task

NOTE: Materials buckets are not compatible with replaceable cutting edges or digging teeth.

Digging teeth can be added to the heavy-duty bucket for easier digging in hard ground or for breaking loose hard-packed materials such as manure or silage. Digging teeth are not compatible with replaceable cutting edges.

Five-tine round bale/silage grapple with grille

Five-tine round bale/silage grapple with grille

All of the H-Series Loaders use the same five-tine pin-on grapple. The advantages of this grapple are:

High-performance operators will choose the five-tine grapple for its increased durability and load-carrying capacity. Advantages include:

The grapple is equipped with twin cylinders to provide excellent clamping force.

NOTE: The center tine of the five-tine grapple is slightly off center to avoid contact with the placement of optional digging teeth.

NOTE: The grapple is not compatible with materials or high-volume buckets.

All R-Series Loaders have to option for loader suspension systems. Activated from the operator station, the suspension system reduces the shock experienced when traversing rough terrain. By reducing this shock, the operator is more comfortable in seat and there is a less likely chance of material loss from the bucket. When carrying gravel to a waterway, an operator may experience spillage from bumpy ground. With the suspension system, the shock of these bumps is lessened and the material is kept safely in the bucket.

Heavy-duty bucket (shown with grapple)

Heavy-duty bucket (shown with grapple)

The high-volume bucket is intended for use with lighter-density high-volume materials. The bucket capacity makes this an effective tool for handling snow, wood shavings, and other loose materials.

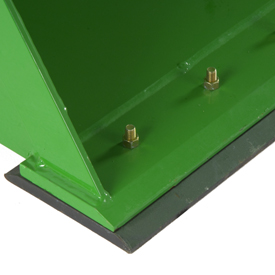

Replaceable wear edge

Replaceable wear edge

For those who frequently scrape on concrete, a replaceable cutting edge will greatly extend the life of the bucket:

Single-point hydraulic connection

Single-point hydraulic connection

The R-Series Loaders feature a single-point hydraulic connection that also incorporates the connection point for any electrical needs. To disconnect the hydraulic connection between the loader and the tractor, it is necessary to relieve the hydraulic system oil pressure on the tractor.

Single-point hydraulic connection

Single-point hydraulic connection

The R-Series Loaders feature a single-point hydraulic connection that also incorporates the connection point for any electrical needs. To disconnect the hydraulic connection between the loader and the tractor, it is necessary to relieve the hydraulic system oil pressure on the tractor.

Lower position without front weight bracket

Lower position without front weight bracket Hood guard with front weights

Hood guard with front weights  Hood guard folded for servicing

Hood guard folded for servicing Hood guard design allows for full lighting

Hood guard design allows for full lightingThe heavy-duty hood guard is compatible with 7030, 7030 Premium, 6615, 6715, 7220, 7320, 7420, and 7520 Tractors.

The basic function is to:

The hood guard:

It is highly recommended to purchase a front weight bracket when using a loader. The hood guard is designed to be slightly rearward of the front weight. This is so the front weight is the first point of contact against lower stationary objects.

If a front weight is not used, the lower bar can be moved downward to improve the protection of the grille below the lights.

The features of the hood guard include:

Hood guard on 6R Tractor

Hood guard on 6R Tractor Hood guard for 6R side view

Hood guard for 6R side viewThe hood guard's basic function is to:

Compatibility:

It is highly recommended to purchase a front weight bracket when using a loader. The hood guard is designed to be slightly rearward of the front weight bracket. This is so the front weight bracket is the first point of contact against lower stationary objects. The height of the hood guard allows better protection for the top of the hood and allows operators to see the top of the hood guard.

The loader hoses are connected to the mid-tractor selective control valves (SCVs).

The loader hoses are connected to the mid-tractor selective control valves (SCVs).

The loader hoses are connected to the mid-tractor selective control valves (SCVs).

Large ballast box is available to carry additional ballast for greater tractor stability.

Capacities | |||

Weight | Sand (Dry) | Concrete | Portland Cement |

BW15852 Large ballast box: | |||

| Volume | 13.3 ft3 = 377L | ||

Material | 581 kg (1277 lb) | 871 kg (1915 lb) | 1089 kg (2395 lb) |

Empty box | 155 kg (342 lb) | 155 kg (342 lb) | 155 kg (342 lb) |

Total | 736 kg (1619 lb) | 1026 kg (2257 lb) | 1244 kg (2737 lb) |

BW15852 Large ballast box is compatible with Category 2 Quik-Couplers and Category 2 or 3 hitches.

See ''Rear Ballast Requirements'' for proper ballasting of the tractor.

If swapping implements quickly is required, look to the hydraulic remote implement latch. Switching from a bucket to a bale spear can now be accomplished quickly, with limited movements of the loader, and without leaving the operator’s seat.

The hydraulic remote implement latch is powered by a hydraulic accumulator, which collects and stores excess oil generated through the normal operation of the boom (curl, dump, lift, lower). To activate the device, the two switches installed in the right-hand side of the operator’s station are pressed simultaneously by the operator. This action releases the oil, and unlocks the implement.

This feature does not require a third-function hydraulic system.

This kit includes the common tractor and loader wiring harness and hardware needed to install loader lights, hydraulic remote implement latch, and loader suspension system. When installing multiple options, only one wiring harness prep package is required.

Repetition. Fatigue. No more.

The second generation of industry-exclusive Return-to-Position (RTP) with ESL will provide a practical solution for customers with daily, repetitive, material handling needs. Think about the commercial hay producer must constantly work the joystick to position the loader to stab the bale, carry the bale, and load the bale. RTP allows the operator to set different points for the loader to move to with the flick of the wrist, activating the detent in electronic joysticks. The loader can be taught that one movement means position for bale spear to stab the bale; another can be set to carry the bale.

With the second generation of RTP, operators can set application profiles. If the loader is used for bale and pallet work the operator can name one set of motions bale spear and the other pallet forks. The different applications have different set points associated with them. With the old system, the set points had to be entered each time for each application.

RTP Gen2 includes ESL. ESL utilizes the sensors placed in the boom for RTP control and allows the operator to turn self-leveling on or off. If the operator likes a mechanical self-leveling loader (MSL) for hay and pallet work, but would rather have the angles of a non self-leveling loader (NSL) when handling earth or barn cleaning, both are possible. Simply activate ESL through the RTP menu when self-leveling is required and then turn it back off when it is not.