We are hiring! Run with Riesterer and Schnell: Apply Today

We are hiring! Run with Riesterer and Schnell: Apply Today

Search

Choose a Location

1Engine power PS (hp ISO) at max engine power speed (ECE-R120). John Deere Standard RES10080, SAE Standards J1995.

Ultimate Comfort and Convenience package

Ultimate Comfort and Convenience packageThe Ultimate Comfort and Convenience package offers unsurpassed visibility, operator comfort, control placement, and ride and sound quality. Features in this package include:

Controls

Displays

Storage

Sound

Outlets

Mirrors

Windows

Lights

For additional attachments and mounting solutions, see Cab convenience or Cab mounting solutions.

Leather seat

Leather seatThe seat improves ride quality and helps to reduce operator fatigue.

Features include:

Bluetooth is a trademark of Bluetooth SIG, Inc. XM is a trademark of Sirius XM Radio, Inc.

Ultimate Visibility package

Ultimate Visibility packageVisibility is one of the most important attributes of the cab. While lighting is a large portion of that, features like windshield wipers, mirrors, sunshades, and cameras are also important to overall visibility. For this reason, John Deere offers three visibility packages on 7 and 8 Family Tractors:

The lighting configurations are available to match various applications and ensure maximum around-the-clock productivity.

Light housings are large, allowing for optimum total lumens and available light. The Select Visibility package uses 65-W halogen bulbs, whereas the Premium and Ultimate Visibility packages use light-emitting diode (LED) lights. The Premium and Ultimate Visibility packages replace Select Visibility package’s halogen lights with LED lights. The only lights that are not LED are the low-beam driving lights; they remain halogen. This allows each LED light to work at a lower temperature and no one light works harder than any other. The uniformity in LED coverage allows only one type of light output surrounding the tractor.

The lighting pattern in the Ultimate Visibility package provides industry-leading performance in nighttime visibility. LED lights provide maximum brightness and a true color output for excellent field definition that is easy on the operator's eyes.

The LED lights provide 40 percent greater coverage width and 10 percent more light coverage in the rear. LED lighting packages use 45 percent less amps than standard halogen lights and have an increased life expectancy over HID lights which leads to lower costs of ownership over the life of the tractor.

The low- and high-beam driving/work lights are adjustable. Please refer to the electrical section in the Operator’s Manual for complete details on adjusting lights.

NOTE: Lighting packages may vary depending on region.

ActiveSeat II and controls

ActiveSeat II and controlsThe John Deere Active Seat II utilizes an electrical control system to control the vertical seat top movement. The "active" control system minimizes vertical seat top acceleration by sensing vertical tractor inputs and actively positioning the seat top to cancel those inputs. This results in a significantly smoother ride for the operator.

The John Deere ActiveSeat II has many of the same features of the air suspension seat with the addition of a ride firmness switch. The ride firmness switch is located on the left-hand armrest and replaces the suspension shock-dampening seat attenuation lever on the front right-hand side of the seat controls.

The ride firmness switch has three positions: plus, minus, and mid position. The three positions provide three different levels of seat performance:

ActiveSeat II left armrest controls

ActiveSeat II left armrest controlsThe ActiveSeat II is also available as a heated and ventilated leather seat for increased comfort and easier cleaning. This is only available with the Ultimate Comfort and Convenience package. For tractor applications where operating speed is not limited by the implement, the ActiveSeat II can allow for faster field speeds and increased overall comfort and productivity.

The leather seat includes massaging capability to alleviate operator fatigue.

Right-hand seat swivel has been improved above current 8R Tractors to 25 degrees (versus 8 degrees) to the left and 40 degrees to the right in the Premium and Ultimate Comfort and Convenience packages.

NOTE: The John Deere ActiveSeat II is not available on track tractors.

CommandARM™ console with CommandPRO control

CommandARM™ console with CommandPRO controlThe unique driving strategy is designed to deliver highest performance in combination with operator comfort making the daily work much easier and efficient.

Driving strategy

Driving strategy| Forward movement | Reverse movement | |

| 1 | Accelerate | Decelerate |

| 2 | Top set speed | Zero speed |

| 3 | Decelerate | Accelerate |

| 4 | Zero speed | Accelerate |

| 5 | Activate set speed | |

| 6 | Select direction | |

| 7 | Inching speed | |

| 8 | Inching speed | |

7R with TLS Plus

7R with TLS PlusThe optional TLS Plus is a fully integrated, self-leveling front suspension system available on 7R Tractors equipped with the 1300 mechanical front-wheel drive (MFWD) axle. TLS Plus provides exclusive front suspension using a hydro-pneumatic self-leveling system to increase productivity and improve ride dramatically. TLS Plus provides more control over the front suspension of the tractor.

TLS Plus increases both transport and field productivity with superior stability, ride, and comfort. Loader operators appreciate the enhanced performance when transporting bales or a full bucket of silage. In the field, the TLS Plus front suspension maintains ground-to-tire contact, enabling more power to the ground.

CommandCenter screen

CommandCenter screenIn the Generation 4 CommandCenter™ Display, the operator is able to select maximum pressure to accommodate for the transfer of heavy loads with minimal front axle movement.

The TLS Plus front axle is available with or without wet-disk front brakes. While TLS Plus is available on all 7R Tractors, it is a requirement for the following:

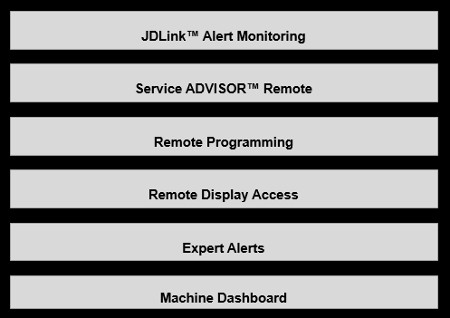

Maximizing uptime for John Deere customers through the use of connectivity and technology

Maximizing uptime for John Deere customers through the use of connectivity and technologyJohn Deere Connected Support is a proactive service approach that utilizes the telematics machine connection to leverage a suite of remote support tools available to improve service efficiency and reduce machine downtime on all 7, 8, and 9 Family Tractors.

You know that when you’re in the field the unexpected can happen. When it does, you need a quick resolution. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you promptly—in the cab or anywhere you are. Better yet, your dealer can receive alerts and connect to your equipment. You know your dealer is always ready to keep you farming – and farming better. Starting with model year 2020, your John Deere tractors will come with a 5-year JDLink™ subscription from the factory that makes this connection possible.

John Deere Connected Support tools

John Deere Connected Support toolsStop fearing the unexpected and start planning for it with the following John Deere Connected Support tools.

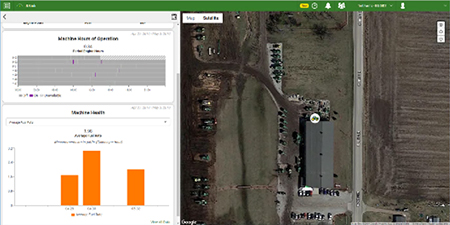

Monitor machines on the go

Monitor machines on the go Connectivity provides data that drives better decisions

Connectivity provides data that drives better decisionsCustomer needs and their success is John Deere’s focus. As functionality becomes more accepted and even expected, that functionality moves from being optional to being included with the machine. In model year 2019, AutoTrac™ guidance and documentation was included on machines equipped with a 4600 CommandCenter™ Display. Five years of JDLink is also included with the purchase of all model year 2020 machines equipped with a 4G LTE Modular Telematics Gateway (MTG). The functionality of JDLink on these machines includes everything that was previously included with JDLink Access + Remote Display Access (RDA) and JDLink Connect subscriptions. This added connectivity enables customers to more easily realize the value of a connected machine.

To use JDLink, the following is required:

The Generation 4 CommandCenter was designed to provide a consistent user experience by providing full-screen viewing of more run page modules, shortcut keys, and precision agriculture capabilities.

Expect easier set-up, along with increased operator confidence, thanks to a simple, customizable interface. The improved design of the Generation 4 CommandCenter also aids in an optimal operating experience and maximizes uptime.

In order to increase your efficiency, take advantage of the following features offered by the Generation 4 CommandCenter:

Layout manager selection page

Layout manager selection page Layout manager module build

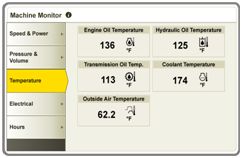

Layout manager module build Machine monitor page

Machine monitor page Work monitor page

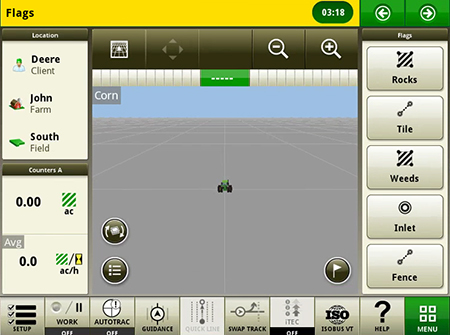

Work monitor page Create flags to mark items in the field

Create flags to mark items in the field Boundary creation from coverage

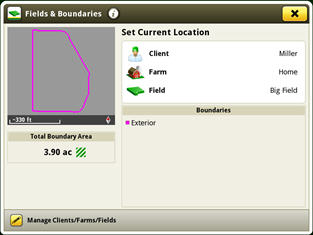

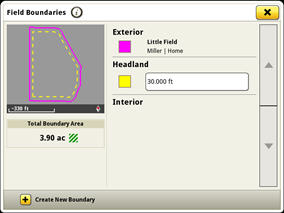

Boundary creation from coverage Headland creation

Headland creation Dual display

Dual displayNOTE: Vehicle applications will always be located on the Gen 4 CommandCenter.

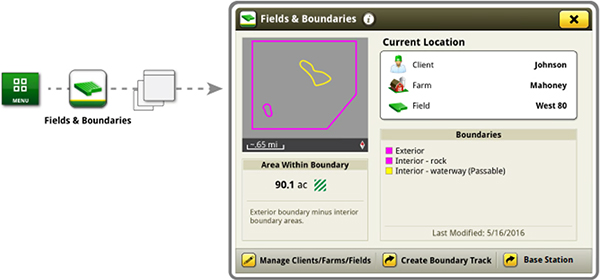

Setup base stations in Fields and Boundaries applications

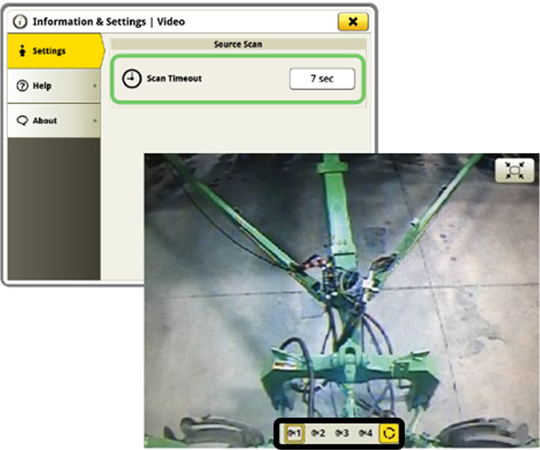

Setup base stations in Fields and Boundaries applications Scan through videos with video looping

Scan through videos with video looping 7 Family Tractor with front hitch

7 Family Tractor with front hitchThe 7 Family Tractors offer two front hitch options to best fit a variety of applications.

Standard (non-ground-engaging) hitch option for applications including, but not limited to:

Premium (ground-engaging) hitch option for applications including, but not limited to:

Premium hitches include a push bar and heavier lift arms:

To ensure adequate hydraulic availability, up to two selective control valves (SCVs) can be included with a front hitch.

Joystick control

Joystick control Paddle pot SCV

Paddle pot SCVTractors equipped with a factory front hitch have the option of selecting a joystick control or paddle pot SCV controls. The joystick control is not compatible with the sixth rear electrohydraulic SCV because of the CommandARM™ controls space required for the front hitch joystick.

StarFire 6000 Integrated Receiver

StarFire 6000 Integrated ReceiverThe John Deere StarFire™ 6000 Integrated Receiver is the new standard in John Deere Precision Ag technology. The integrated design further enhances the value that you have come to expect from StarFire products.

The StarFire 6000 Integrated Receiver eliminates all setup, installation, and calibrations. There is no need to verify machine and receiver measurements, as this has been done precisely for you at the factory. You will spend 60 minutes less per receiver move each season, which gives you more time to focus on other parts of your operation.

With updated Ethernet connectivity, software updates are easier and faster. StarFire 6000 Integrated Receiver maintains the speed to update software in under 4 minutes while remaining in the cab. Over-the-air updates are 85 percent faster with the StarFire 6000 Integrated Receiver because of Ethernet connectivity.

| Key Specs | 7r-270-tractor Current Model |

|---|---|

| Engine description | John Deere PowerTech™ PSS (B20 Diesel Compatible) 6.8L |

| Engine displacement | 6.8 L 415 cu in. |

| Rated engine power | ECE-R120: 199 kW 270 hp |

| Maximum engine power | ECE-R120: 218 kW 297 hp |

| Rated PTO power (hp SAE) | 167 kW 224 hp |

| Maximum PTO power | |

| Transmission type | Standard: John Deere e23™ 42 km/h 26 mph Optional: John Deere e23 transmission 50 km/h 31 mph John Deere Infinitely Variable Transmission (IVT™) 0.050-42 km/h (0.030-26 mph) John Deere Infinitely Variable Transmission (IVT) 0.050-50 km/h (0.030- 31 mph) |

| Hydraulic pump rated output | Standard: 63 cc: 162 L/min 43 gpm Optional: 85 cc: 222.3 L/min 59 gpm |

| Rear hitch category (SAE designation) | Standard: Category 3N/3 with Quik-Coupler Optional: Category 3/3N with hook ends Category 3N/3 with hook ends |

| Base machine weight | e23, TLS™, 18.4R46: 10,000 kg 22,000 lb |

| Engine specifications | |

| Description | John Deere PowerTech™ PSS (B20 Diesel Compatible) 6.8L |

| Engine type | Diesel, in-line, 6-cylinder, wet-sleeve cylinder liners with four valves in head |

| Engine family | JJDXL06.8309 |

| Rated speed | 2100 rpm |

| Aspiration | Dual turbochargers, variable geometry turbo with fixed geometry turbo in series |

| Cylinders liners | |

| Emission level | Final Tier 4 |

| After treatment type | Diesel oxidation catalyst (DOC)/diesel particulate filter (DPF) |

| Displacement | 6.8 L 415 cu in. |

| Engine performance | |

| Rated power | ECE-R120: 199 kW 270 hp |

| Rated PTO power (hp SAE) | 167 kW 224 hp |

| Maximum PTO power | |

| Intelligent Power Management (available in transport and/or mobile PTO applications) | |

| Power boost | 22.4 kW 30 hp |

| Maximum engine power | ECE-R120: 218 kW 297 hp |

| Engine peak torque | At 1600 rpm: 1245 Nm 918 lb-ft |

| PTO torque rise | 40 percent |

| Transmission | |

| Type | Standard: John Deere e23™ 42 km/h 26 mph Optional: John Deere e23 transmission 50 km/h 31 mph John Deere Infinitely Variable Transmission (IVT™) 0.050-42 km/h (0.030-26 mph) John Deere Infinitely Variable Transmission (IVT) 0.050-50 km/h (0.030- 31 mph) |

| Reverser | |

| Clutch; wet/dry | |

| Creeper | |

| Hydraulic system | |

| Type | Closed-center, pressure/flow compensated system with load sensing |

| Pump rated output | Standard: 63 cc: 162 L/min 43 gpm Optional: 85 cc: 222.3 L/min 59 gpm |

| Available flow at a single rear SCV | 132 L/min 35 gpm |

| Available flow at front SCVs | 126 L/min 33 gpm |

| Number of rear selective control valves (SCVs) | Standard: Four SCVs Optional: Three to six ISO couplers: 12.7 mm 1/2 in. Five ISO couplers (SCV 1: 19-mm [3/4-in.] couplers, SCV 2-5: 12.7-mm [1/2-in.] coupler) |

| Number of mid selective control valves (SCVs) | |

| Number of front selective control valves (SCVs) | One with front hitch |

| Joystick SCV control | |

| SCV control | Electronic |

| Rear hitch | |

| Hitch draft control load sense type | |

| Remote control valves available | |

| Hitch category (SAE designation) | Standard: Category 3N/3 with Quik-Coupler Optional: Category 3/3N with hook ends Category 3N/3 with hook ends |

| Maximum lift capacity behind lift points | Standard (Category 3): 6894 kg 15,200 lb Optional (Category 3N): 7847 kg 17,300 lb Standard (Category 3 with hook ends): 6894 kg Optional (Category 3 with hook ends): 7847 kg |

| Lift capacity at standard frame | |

| Sensing type | Electrohydraulic |

| Rear axle differential lock | |

| Drawbar | |

| Drawbar category | Standard: Category 3 Optional: Category 3 with heavy-duty support Category 4 |

| Maximum vertical load | Standard: Category 3: 1837 kg 4050 lb Optional: Category 3 with heavy-duty support: 4536 kg 10,000 lb |

| Rear power take-off (PTO) | |

| Type | Independent Standard: 44.45 mm (1.75 in.) 20-spline, 1,000 rpm Optional: 44.45 mm (1.75 in.), 20-spline, 1,000 rpm capable of 35 mm (1.375 in.) 540/1000 rpm 44.45 mm (1.75 in.) 20-spline, 1000 rpm with 35-mm (1.375-in.) 540E/1000/1000E rpm gearcase 44.45 mm (1.75 in.) 20-spline, 1000 rpm with 35-mm (1.375-in.) 540/540E/1000 rpm gearcase |

| Engine rpm (at rated PTO speeds) | 540/1000 PTO rpm at 1950 engine rpm 540E/1000E PTO rpm at 1750 engine rpm |

| Multispeed PTO option availability | |

| Ground speed PTO option availability | |

| PTO actuation | Electric switch with adjustable modulation |

| Front hitch | |

| Category | Category 3N, ground engaging |

| Electric power | Seven-pin connector |

| Standard lift capacity | 5,200 kg 11,464 lb |

| Front power take-off (PTO) | Available Optional: 44.45 mm (1.75 in.), 20 spline, 1,000 rpm, counter-clockwise rotation (when facing PTO) 35 mm (1.375 in.) 21 spline, 1,000 rpm, counter-clockwise rotation (when facing PTO) 35 mm (1.375 in.) 6 spline, 1,000 rpm, counter-clockwise rotation (when facing PTO)** |

| PTO speed | 1,000 PTO rpm at 1940 engine rpm |

| Rear axle | |

| Type | Standard: Rack-and-pinion or flange axles Optional: Diameter: 110 x 2550 mm 4.33 x 100.4 in. Diameter: 110 x 3010 mm 4.33 x 118.5 in. Diameter: 120 x 2550 mm 4.72 x 100.4 in. Diameter: 120 x 3010 mm 4.72 x 118.5 in. Flanged axle: 335 mm (13.2 in.) |

| Final drive type | Inboard planetary three pinion |

| Differential controls | |

| Axle type | |

| Brakes, type and control | |

| Rear differential lock | Full-locking electrohydraulic |

| Load rating | |

| Front axle | |

| Type | Standard: 1300 Series MFWD: tread range 1524 to 2235 mm 60 to 88 in. Optional: TLS: Tread range 1524 to 2235 mm TLS with front brakes available with 40 km/h 24.9 mph TLS with front brakes standard with 50 km/h 31 mph |

| Front axle differential lock | 1300 Series MFWD: Limited slip TLS: Limited slip TLS with front brakes: Full-locking electrohydraulic (actuated at same time as rear diff lock) |

| Load rating | |

| Tires | |

| Front | RCI Group 42/43/44 |

| Rear | RCI Group 47/48/49 |

| Wheel tread range | |

| Turning radius with brakes | 380/85R34 group 42 tires at 152.4-cm (60-in.) spacing, 1300: 7 m 23 ft 600/70R30 group 43 tires at 188.2-cm (74.1-in.) spacing, TLS: 6.7 m 22 ft 620/75R30 group 44 tires at 208.3-cm (82-in.) spacing, TLS: 8.7 m 28.5 ft |

| Turning radius without brakes | |

| Tracks | |

| Tread spacing | |

| Drive type | |

| Track width | |

| Midrollers | |

| Steering | |

| Electrical system | |

| Alternator size | Standard: 210 amp Optional: 250 amp |

| Battery options | 12 V |

| Working lights | Standard: 18 halogen Available: 18 LED or 22 LED |

| Type of bulb in headlight (Halogen, Zenon, LED) | Standard: 65-W halogen Available: LED |

| Type of bulb in beacon (Halogen, Zenon, LED) | |

| dB(A) rating for backup alarm | |

| Total cold cranking amps | With two 925 CCA group 31 batteries: 1850 CCA |

| Operator station | |

| Rollover protective structure, OOS | |

| Seat | Degree of seat swivel, left hand 25 degree Degree of seat swivel, right hand 40 degree Standard: air suspension Optional: ActiveSeat™ II |

| Cab suspension | Optional |

| Instructional seat | Standard |

| Display | Standard: 4100 Generation 4 CommandCenter™: 17.8 cm 7 in. Optional: 4600 Generation 4 CommandCenter: 25.4 cm 10 in. |

| Radio | Standard: AM/FM stereo with weatherband, remote controls, auxiliary input jack, four speakers and external antenna |

| Inner cab volume | 3.24 m3 114 cu ft |

| dB(A) rating | |

| Cab glass area | 6.56 m2 70.61 sq ft |

| Safety glass rating | |

| Front visibility | |

| Dimensions | |

| Wheelbase | 2925 mm 115.2 in. |

| Overall length | 5540 mm 218 in. |

| Overall height | |

| Drawbar clearance | Group 47 rear tires: 360 mm 14.2 in. Group 48 rear tires: 415 mm 16.3 in. Group 49 rear tires: 461 mm 18.1 in. |

| Front axle center | |

| Approximate shipping weight, Open;Cab | |

| Weight | |

| Base machine weight | e23, TLS, 18.4R46: 10,000 kg 22,000 lb |

| Maximum ballast level | SAE PTO hp: 65.8 kg 145 lb |

| Maximum permissible weight | |

| Capacities | |

| Crankcase oil volume | 26 L 6.9 U.S. gal. |

| Fuel tank | e23™: 463 L 122 U.S. gal. IVT: 513 L 135 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | 26.2 L 6.9 U.S. gal. |

| Cooling system | 39.5 L 10.4 U.S. gal. |

| Transmission-hydraulic system | 160 L 42.3 U.S. gal. |

| Serviceability | |

| Interval for engine oil change | 500 hours |

| Interval for hydraulic/transmission oil change | 1,500 hours |

| Interval for engine coolant change | 6,000 hours |

| Loaders | |

| Loader | H480 |

| Lift capacity at full height | 2411 kg 5315 lb |

| Maximum lift height | 4704 mm 185.2 in. |

| Precision AG | |

| Guidance | Integrated AutoTrac™ |

| Telematic | JDLink™ |

| Remote diagnostics | ServiceADVISOR™ Remote: available with JDLink hardware and activations Remote Display Access: available with JDLink hardware and activations |

| Miscellaneous | |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Country of manufacture | USA |