We are hiring! Run with Riesterer and Schnell: Apply Today

We are hiring! Run with Riesterer and Schnell: Apply Today

Search

Choose a Location

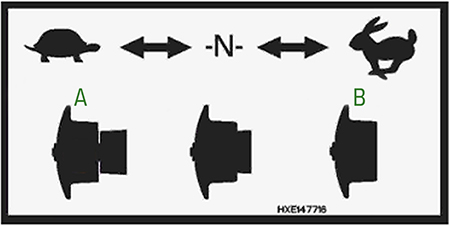

Increase grain in the tank with a two-speed center feed section. A slow-speed setting softens the impact of crop fingers and drum flighting when engaging with crop. This ensures that easy-shelling crops like lentils and soybeans do not get thrown over the feederhouse. Use the high-speed setting in canola or high-yielding cereals to prevent slug feeding while ensuring that the drum does not plug.

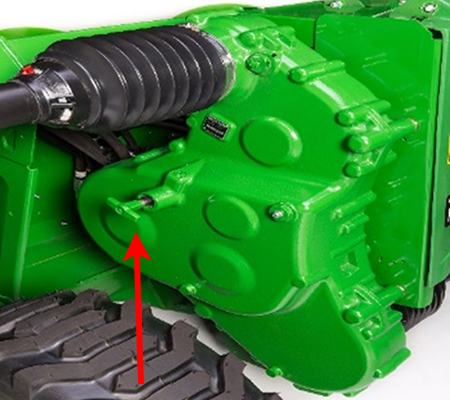

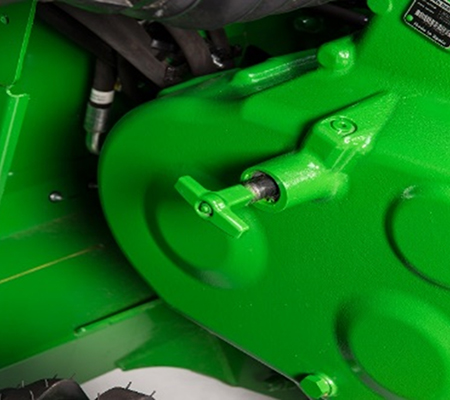

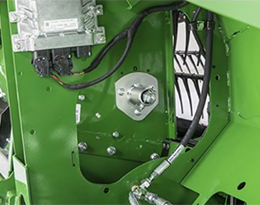

Toolless shifting on the gearcase

Toolless shifting on the gearcase

Toolless shifting on the gearcase

Toolless shifting on the gearcase

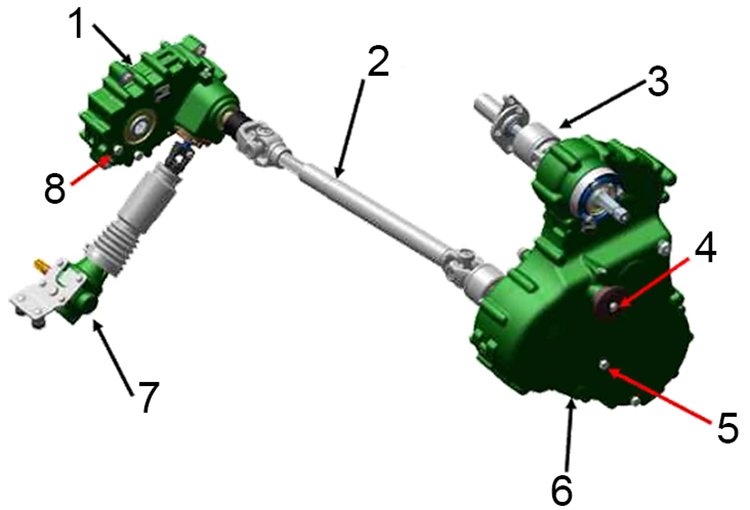

Center crop flow divider

Center crop flow divider

Two-speed center feed section (A is pulled out and B is pushed in)

Two-speed center feed section (A is pulled out and B is pushed in)

|

Low speed |

High speed |

Feed drum |

200 rpm |

240 rpm |

Center feed belt |

1000 rpm |

1200 rpm |

|

RDF |

HDR |

Feed drum torque |

1650 Nm (1217 lb-ft) |

2860 Nm (2109.4 lb-ft) |

Center belt width |

177.8 cm (70 in.) |

200.9 cm (79.1 in.) |

Appropriately set feed drum height for varying crops during harvest with the RDF dual-position feed drum.

Feed drum and floor

Feed drum and floor

Retractable feed drum fingers

Retractable feed drum fingers

Feed drum controls and slip clutch

Feed drum controls and slip clutch

Connected Support technology

Connected Support technology

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink™ telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.

Achieve superior ground following when harvesting in a wide range of terrains, crops, and conditions with RDF HydraFlex Draper Platforms. HydraFlex is an industry-exclusive hydraulic float system.

HydraFlex draper system floats with the terrain

HydraFlex draper system floats with the terrain

Hydraulic float arm

Hydraulic float arm

Adjust ground pressure by changing hydraulic pressure in the float arm cylinders

Adjust ground pressure by changing hydraulic pressure in the float arm cylinders

Help bushy crops, especially heavy canola, feed evenly into the feederhouse with an optional 45.7-cm (18-in.) top auger extending the full width of the draper.

RDF top auger

RDF top auger

| Key Specs | rd45f-hydraflex-draper Current Model |

|---|---|

| Cutterbar length | 13.72 m 45 ft |

| Knife drive | Double-cut, dual-drive, shaft-driven cutterbar: 10.2 cm 4 in. |

| Knife speed | X Series Combine: 520 cycles/min S-Series Combine: 490 cycles/min |

| Pickup reel operating speeds | 6-70 rpm |

| Draper belts speed control | Hydraulic from cab (side belts only) |

| Platform | |

| Cutterbar | |

| Type | Straight-line knife drive system Cutterbar vertical flex: 190 mm 7.5 in. |

| Length | 13.72 m 45 ft |

| Knife drive | Double-cut, dual-drive, shaft-driven cutterbar: 10.2 cm 4 in. |

| Knife speed | X Series Combine: 520 cycles/min S-Series Combine: 490 cycles/min |

| Cutterbar tilt | |

| Pickup reel | |

| Number of slats | Six bat poly |

| Fingers | Nylon |

| Diameter | 106.7 cm 42 in. |

| Height control | Hydraulic |

| Speed control | Hydraulic |

| Reel lift | 72 cm 28.3 in. |

| Reel fore and aft | 35.9 cm 14.1 in. Fore of the cutterbar: 40.6 cm 16 in. |

| Reel resume | Base |

| Reel reverse | Base |

| Operating speeds | 6-70 rpm |

| Operating speeds (54-in. reel) | |

| Slat reel | |

| Number of slats | |

| Diameter | |

| Height control | |

| Speed control | |

| Operating speeds | |

| Draper belts | |

| Width | Side belts: 101.6 cm 40 in. Center belts: 177.6 cm 70 in. |

| Belt depth | 101.2 cm 39.8 in. |

| Cleat height | 19.05 mm 0.75 in. |

| Operating speed | Side belts (variable): 1-3.5 m/s 3.3-11.5 fps Center belts: 211 m/min 692 fpm Low-speed center belt (fixed): 4.2 m/s 13.8 ft High-speed center belt (fixed): 5.1 m/s 16.7 fps |

| Speed control | Hydraulic from cab (side belts only) |

| Center belt reverse | Base |

| Feed drum | |

| Diameter | 414 mm 16.3 in. |

| Feed drum fingers | Heavy-duty and round with breakaway notch and retainer Diameter: 16 mm 0.625 in. |

| Number of fingers | 21 |

| Auger finger platform | Triple chevron, retracting |

| Finger reach | 152 mm 6 in. |

| Drum/auger reverse | Base |

| Operating speed | Low speed: 200 rpm High speed: 240 rpm |

| Center clean out door | Base |

| Header height sensing | |

| Type | Electrohydraulic |

| Header height sensing on the ground | Base |

| Header height sensing off the ground | Optional: four sensors |

| Auxiliary top auger | |

| Type | Optional: hydraulic drive |

| Fingered augers | |

| Size | 45.7 cm 18 in. |

| Dimensions | |

| Platform length | 14.6 m 47.9 ft |

| Overall operating depth | With dividers: 2.74 m 9 ft |

| Transport width, field position | 14.6 m 47.9 ft |

| Transport width on wheel, less dividers | |

| Transport length, hitch extended | |

| Weight | |

Center section seal kit

Center section seal kit

Minimize grain loss when straight cutting canola, oil seed, lentils, and peas with a center section seal kit.

Save $330 USD ($465 CAD) a year across 607 ha (1,500 acres) by reducing canola center section losses up to 45 percent with a center section seal kit. Maximize performance in straight-cut canola by pairing the center section seal kit with top augers.

In crops other than canola, oil seed, lentils, and peas (mainly wheat), there is an increased risk of side belt underfeeding pending conditions.

Help bushy crops, especially heavy canola, feed evenly into the feederhouse with an optional 45.7-cm (18-in.) top auger extending the full width of the draper.

RDF top auger

RDF top auger

Gently engage in crops with a low-profile yet strong and durable poly-tine pickup reel.

| Small grains, canola, and pulse crops | Soybeans and on-ground crops | |||

| Reel | Standard | Flip-over | Standard | Flip-over |

| Wrapping | Better | Best | Good | Best |

| Down crop | Better | Better | ||

| Side belt feeding | Better | Good | Better | |

| Plant tossing | Better | Good | Better | |

| Shatter loss | Better | Better | ||